EPA waste data release, June 2024. Latest reference year 2022.

Waste tyres pose a threat to the atmosphere, to land, soil, water, plants and animals if they are not managed properly. Where they are dumped in our environment, they have a significant negative visual impact on our landscape. Tyres become waste when worn-out tyres on a vehicle are replaced; and, unless reused, they become waste when the vehicle they are on is transferred to an authorised treatment facility. Our section on end-of-life vehicles provides more information on end-of-life vehicles arising in Ireland, and reuse, recycling and other recovery of this waste.

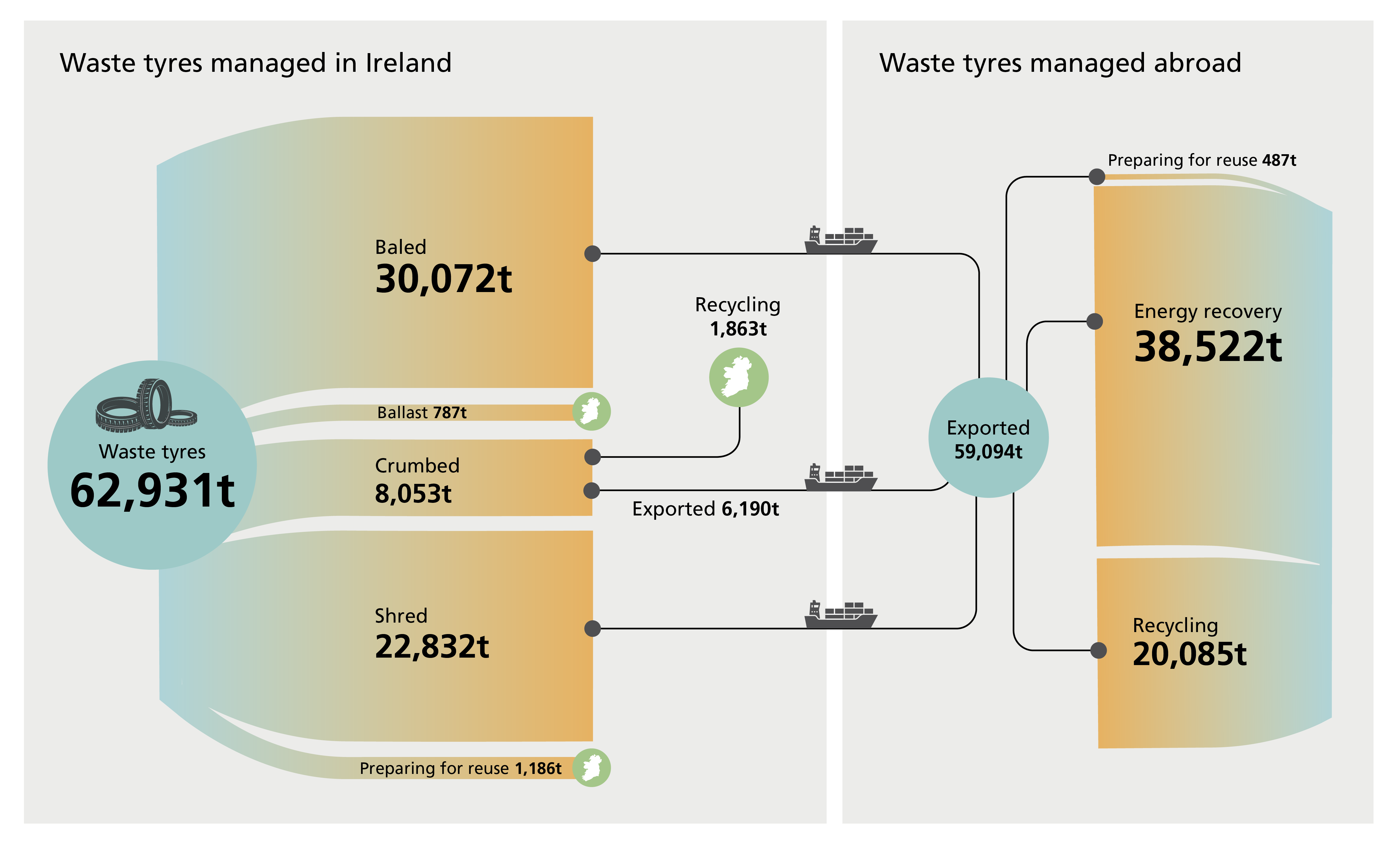

Figure 1 shows how waste tyres moved through the waste treatment network in Ireland in 2022. Most waste tyres are collected by authorised waste collectors and brought to a waste facility; and, unless they are used as ballast or prepared for reuse, they are either baled or pre-treated before the final treatment step.

The most common treatment route in 2022 was baling of waste tyres at Irish waste facilities followed by export and final treatment abroad. This accounted for 48 per cent of the waste tyres managed in 2022. The second most common treatment route was shredding of waste tyres in Ireland followed by export. This accounted for 36 per cent of waste tyres managed in 2022. It is reported that this is currently the most economically viable strategy for waste tyre treatment operators.

Figure 1. Waste Tyre management in Ireland 2022

Waste tyre final treatment activity 2022

| Waste tyre final treatment activity 2022 | Quantity (tonnes) | Percentage of managed |

| Prepared for reuse | 1,673 | 2.7% |

| Recycled | 21,949 | 34.9% |

| Ballast | 787 | 1.3% |

| Used as a fuel | 38,522 | 61.2% |

| TOTAL | 62,931 | 100.0% |

To ensure that waste tyres are handled in an environmentally sound manner, a producer compliance scheme for tyres and waste tyres, operated by Circol ELT (previously Repak ELT), was introduced in October 2017, underpinned by the Tyres and Waste Tyres Regulations 2017. 2018 is the first full calendar year that Circol ELT was in operation. The scheme currently only includes car and motorcycle tyres and does not account for truck, agricultural or construction tyres (note: the EPA data presented encompasses data on all types of waste tyres managed in 2022). The Waste Action Plan for a Circular Economy includes a commitment that the tyres producer compliance scheme will be extended to all categories of tyres provided for by the Tyres Regulations (passenger car, van, 4x4, truck, bus, agricultural and motorcycle tyres).

The EPA data on waste tyres draw on multiple sources including EPA surveys, data from the National Waste Collection Permit Office, data on exports from the National Transfrontier Shipments Office, and information from the tyres producer compliance scheme Circol ELT.

There are no statutory recycling or recovery targets set down in the Tyres Regulations[1]. However, Circol ELT’s Ministerial approval obligates the compliance scheme to meet minimum targets for the type of tyres it covers. By the end of 2019, and each subsequent year, it must achieve: